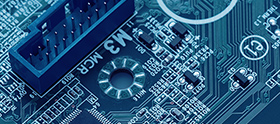

The electronic semiconductor production workshop has extremely strict requirements for the environment, which can be regarded as the ultimate demand for the production environment in modern industry. Any pollutant that is insignificant in the macroscopic world is a huge disaster in the nanoscale semiconductor world.

Factory building design specification standards

"Code for Design of Clean Rooms in Electronic Industry" (GB 50472) :

It is the fundamental law for the design of clean workshops in China's electronics industry, clearly stipulating the requirements for air cleanliness grades in the production of various electronic products.

"Code for Design of Clean Rooms" (GB 50073)

It is a more universal design standard for cleanrooms.

Lin Sen Purification Group is committed to becoming the most influential comprehensive solution provider in the global cleanroom system field. It can tailor clean air solutions for the special production needs of global electronic semiconductor cleanrooms.

As a state-controlled high-tech enterprise, Hikvision Robotics is part of the Hikvision system, a global leader in security and intelligent Internet of Things. It is a technical benchmark and product solution provider in the domestic machine vision and mobile robot fields.

The company's business covers the global market. It is not only a key driver of the intelligent manufacturing industry, but also represents China's advanced level in high-precision sensing, intelligent navigation and industrial Internet of Things applications.

As a leading enterprise in domestic intelligent manufacturing, Hikrobot has invested in building its own intelligent manufacturing (Tonglu) base project to further consolidate its intelligent manufacturing capacity layout. The planned construction area is approximately 310,000 square meters, which will be used to build HikRobot's intelligent manufacturing factory.

Hikrobot's requirements for the production environment far exceed the standards of conventional electronic manufacturing. Its production workshop must meet extremely strict cleanliness, temperature and humidity stability, and static electricity protection and other multiple indicators to ensure that the precision instruments involved in mobile robots and machine vision products have zero defects and high reliability during the manufacturing process.

Lin Sen Purification Group provides for Hikrobot

Professional and customized purification solutions

In response to the strict requirements of customers for clean environments during the production process of mobile robots and machine vision products, Linsen Purification Group, based on the on-site conditions of the project, has provided professional and customized purification solutions to ensure that the production environment in the workshop precisely matches the application needs of customers.

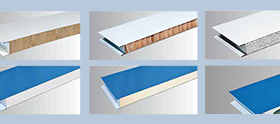

The surface of the anti-static purification board is coated with a high-performance anti-static coating, which offers excellent anti-static protection. It does not produce or accumulate dust, providing a dust-free and stable environment for the production workshop and improving the yield of high-quality products.

High-quality filling core materials help maintain a constant temperature and humidity in the workshop and create a stable production environment. The fire resistance duration reaches one hour, enhancing the safety of the factory building.

It can be modularly installed, maintaining the integrity and aesthetics of the workshop environment. The appearance is smooth, avoiding dust accumulation in dead corners, and meeting the basic principle of a clean room that "all surfaces can be cleaned".

The purification color steel plate door of Lin Sen Purification Group adopts three-sided self-foaming rubber strip sealing technology, which can achieve an extremely high density between the door leaf and the door frame, effectively preventing the inflow of external non-clean air and the outflow of internal clean air, maintaining the positive pressure and cleanliness level required for the production environment.

It has excellent sound insulation, heat preservation and heat insulation properties, which help maintain a stable temperature and humidity in the workshop, reduce the energy consumption and load of the air conditioning system, and create a quiet and stable production environment as a whole.

The door body of Lin Sen Purification Group's purification color steel plate door is made of high-quality cold-rolled steel plate and has undergone special treatment. The surface is smooth, flat, free of pores and does not produce dust. It has met the strict requirements of the customer's workshop for building materials to "not produce dust and not accumulate dust".

Lin Sen Purification Group specializes in electronic semiconductors

Clean workshops provide reliable protection

As a professional provider of comprehensive cleanroom system solutions, Lin Sen Purification Group, based on its profound understanding of the manufacturing characteristics of the electronic semiconductor industry, has tailored a professional purification enclosure system solution for the Hikrobot Intelligent Manufacturing (Tonglu) Base project.

In the future, Lin Sen Purification Group will continue to deepen its system service capabilities and in-depth understanding in the field of electronic semiconductors. At present, our clean solutions have been serving multiple electronic semiconductor industrial bases worldwide. Linsen Purification Group will continue to assist precision manufacturing enterprises in enhancing their competitiveness.

Honesty builds the forest

Quality wins the world

Lin Sen Purification Group, having been deeply engaged in the clean industry for over two decades, is committed to becoming the most influential comprehensive solution provider in the global cleanroom system field. Core business coverage: pharmaceuticals and biological products, medical devices and hospitals, biological laboratories and CMC centers, electronic wafers and new energy, food and cosmetics, aerospace and precision machinery.

The group integrates design and research and development, product manufacturing, and engineering general contracting. Relying on the CNAS certified testing center, the quality of its products continuously meets international authoritative standards, leading the development of the industry. The group has established a rapid response mechanism (24-hour delivery support) and outstanding performance capabilities for large and complex projects. Its member units operate independently and complement each other in a coordinated manner, providing customers with efficient and stable cluster services.