On November 14th, the "Intelligent Pharmaceutical Future · Innovative Brilliance" - "Huangli Voice" 2025 Pharmaceutical Engineering Technology Exchange Conference (Suzhou Station), hosted by Sinopharm Engineering and organized by Linsen Purification Group, was a complete success. This conference attracted over a hundred pharmaceutical enterprises from East China and more than 400 experts in the pharmaceutical industry. They engaged in in-depth exchanges and discussions on core topics such as the cutting-edge technologies and development trends of pharmaceutical engineering.

Chen Jinhui, the Party Secretary and Director of Sinopharm Engineering, delivered a speech

In his opening remarks, Chen Jinhui, the Party Secretary and Director of Sinopharm Engineering, pointed out that currently, the global pharmaceutical industry is undergoing a dual transformation of breakthroughs in biotechnology and upgrades in intelligent manufacturing. The post-pandemic era has also put forward higher requirements for the resilience of the supply chain. The industry is faced with both opportunities and challenges. He said that this year marks the final year of the 14th Five-Year Plan and the year for planning and laying out the 15th Five-Year Plan. This exchange meeting is an important platform for gathering industry wisdom and jointly exploring the path of high-quality development in the new era, which will help the pharmaceutical engineering industry steadily move towards intelligence and greenness.

Liu Jia from Lin Sen Purification Group delivered a speech

In his opening remarks, Mr. Liu Jia, the general manager of Lin Sen Purification Group, pointed out that in today's era when artificial intelligence and big data are reshaping all industries, the pharmaceutical industry is undergoing a historic leap from "manufacturing" to "intelligent manufacturing". He emphasized that in the future, smarter, more efficient and safer methods must be adopted to create more reliable engineering and higher-quality drugs, thereby benefiting a wider range of people and driving China's pharmaceutical industry towards a smarter and more brilliant future.

This exchange meeting is an important platform for building consensus and stimulating innovation. We look forward to working with colleagues in the industry to explore new paths for high-quality development through in-depth exchanges and intellectual collisions, and to help China's pharmaceutical industry steadily move towards a smarter, greener and more brilliant future.

The grandeur of the conference

During the exchange meeting, the experts in attendance focused on the cutting-edge of the industry and conducted multi-dimensional and in-depth discussions on hot topics such as "Application of New Technologies in Pharmaceutical Factories", "Construction and management of Overseas Bases", and "Digital Construction Practices". The on-site thinking was intense and the interaction was lively. Cutting-edge viewpoints and practical experiences interwove and collided, continuously pushing the atmosphere of the venue to new heights.

Representatives from several enterprises expressed during the exchange that this "Voice of the Oriole" conference is not only a feast of ideas but also a bridge of connection. It precisely provides enterprises with a forward-looking technical perspective and highly valuable practical cases for reference. At the same time, it has more efficiently facilitated the precise matching of internal resources and communication of intentions within the industry, laying a solid foundation for building a new pattern of win-win development in the future.

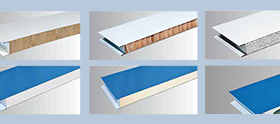

Lin Sen Purification Group, having been deeply engaged in the clean industry for over two decades, is committed to becoming the most influential comprehensive solution provider in the global cleanroom system field. Core business coverage: pharmaceuticals and biological products, medical devices and hospitals, biological laboratories and CMC centers, electronic wafers and new energy, food and cosmetics, aerospace and precision machinery.

The group integrates design and research and development as well as product manufacturing. Relying on the CNAS certified testing center, the quality of its products continuously meets international authoritative standards, leading the development of the industry. The group has established a rapid response mechanism (24-hour delivery support) and outstanding performance capabilities for large and complex projects. Its member units operate independently and complement each other in a coordinated manner, providing customers with efficient and stable cluster services.