From June 18 to 19, the special training of "lean production training camp" of Wujiang District SME Service Alliance entered Linsen purification, and more than 50 enterprise heads and managers from the whole region participated in the training.

本次培训,邀请到了SKO精益专家周家东老师主讲,周老师曾任丰田九州工厂新员工培训教官,长期致力于中国制造业精益管理和智能制造水平的落地咨询及提升指导,是清华大学深圳研究生院、浙江大学、浙江工业大学等高校精益管理相关课程的特约讲师。

The training mainly focuses on the lean production, talent training and quality management in the process of intelligent manufacturing.

Using the teaching method of simple and easy, Mr. Zhou combined theory with practice, and explained with a large number of practical cases how enterprises should improve the waste in the process of daily production management through lean production management, so as to reduce production costs and improve profit margins. And what methods and means should enterprises use to train their employees, so as to achieve the inheritance and improvement of technology.

The trainees listened and recorded, and also had on-site communication with the teachers on the problems encountered in the operation of the company from time to time.

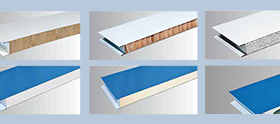

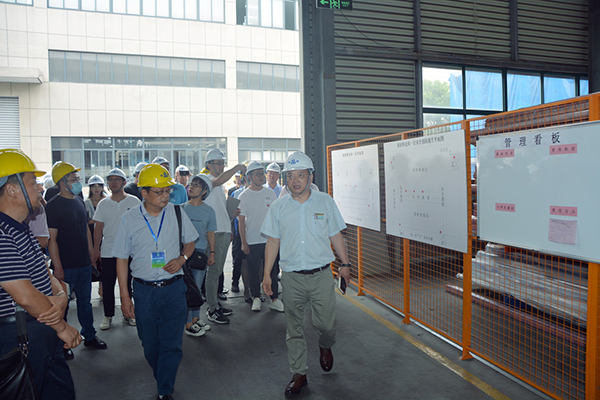

During the meeting, director Xu of Linsen purification led the participants to visit the exhibition hall and production workshop of Linsen purification, and introduced the products of Linsen purification and the standardized management of the workshop. We go to the production line to find problems, difficulties and pain points, go back to the classroom to discuss solutions, and then go to the site to verify the feasibility and explore the in-depth integrated development of production and education.

The trainees said that through this training and learning, theory and practical operation, they had a deeper understanding of lean production management, a more rational understanding and more thinking. Linsen purification will also hold some lean production training internally in the future, so as to master the essence of lean production system as soon as possible and obtain the power to implement lean, so as to help standardize workshop management, improve the core competitiveness of enterprises and promote the successful implementation of lean transformation.