The emergence and development of all technologies are based on the needs of production. Clean room technology is no exception. During the Second World War, the air floated gyroscopes for aircraft navigation produced by the United States had to be reworked 120 times for every 10 gyroscopes due to their unstable quality. During the Korean Peninsula war in the early 1950s, more than one million electronic components were replaced in 160000 electronic communication equipment in the United States. The time of radar failure accounted for 84% and submarine sonar failure accounted for 48%. The reason is that the reliability of electronic devices and parts is poor and the quality is unstable. After investigating the reasons, the military and manufacturers finally determined that it was related to the unclean production environment from many aspects. Although at that time, all kinds of strict measures were taken to close the production workshop, but little effect was achieved.

So there was the birth of a clean room!

Phase I

It was not until the early 1950s that the HEPA high efficiency particulate air filter developed by the American Atomic Energy Commission in 1951 was applied to the air supply filtration of the production workshop to solve the problem of capturing radioactive dust harmful to human body.

Phase II

In 1961, Willis Whitfield, a researcher at Sandia National Laboratories, proposed a clean air flow organization scheme called laminar flow at that time and now called unidirectional flow, which was applied to practical engineering. Since then, the clean room has reached an unprecedented higher level of cleanliness.

Phase III

In the same year, the U.S. air force formulated and issued the world clean room standard to-00-25 -- 203 air force directive "standard for design and operation characteristics of clean room and clean workbench". On this basis, the American federal standard fed-std-209, which divides the clean room into three levels, was published in December 1963. So far, the rudiment of perfect clean room technology has been formed.

The above three key advances are often known as the three milestones in the development history of modern clean rooms. In the mid-1960s and 1920s, clean rooms mushroomed in the United States and are now springing up in various industrial departments. It was not only used in military industry, but also popularized in electronic, optical, micro bearing, micro motor, photosensitive film, ultrapure chemical reagent and other industrial departments, which greatly promoted the development of science, technology and industry at that time. Therefore, the following is a detailed introduction at home and abroad.

Development comparison

our country

From the early 1960s to the late 1970s, this decade was the starting and foundation stage of China's clean technology. About ten years later than abroad. It was a very special difficult era, with weak economy and no power diplomacy. Under such difficult conditions, China's clean technology workers began their own entrepreneurial process around the needs of precision machinery, aviation instruments and electronic industry.

From the late 1970s to the late 1980s, China's clean technology has experienced a sunny development stage. In the development process of China's clean technology, many landmark important achievements were almost born at this stage. The index reached the technical level of foreign countries in the 1980s.

Since the early 1990s, China's economy has always maintained stable and rapid growth, and international investment has been continuously injected. A number of multinational groups have successively built many microelectronic factories in China. Therefore, domestic technicians and researchers have more opportunities to directly contact the design concept of foreign clean rooms and understand the world's advanced equipment and devices, management and maintenance, etc.

abroad

In the early 1950s, in order to solve the problem of collecting radioactive dust harmful to human body, the American Atomic Energy Commission came out in 1950 with the advent of high efficiency particle air filter (HEPA), which has become a milestone in the development history of clean technology.

In the 1960s, clean rooms in factories such as electronics and precision machinery in the United States sprung up, and the process of transplanting industrial clean room technology to biological clean rooms began. In 1961, laminar flow (unidirectional flow) clean room was born. The earliest clean room standard in the world - US Air Force Technical Regulation 203 was formed.

In the early 1970s, the focus of clean room construction began to shift to medical, pharmaceutical, food and biochemical industries. In addition to the United States, other advanced industrial countries, such as Japan, Germany, Britain, France, Switzerland, the former Soviet Union and the Netherlands, also attach great importance to and have vigorously developed clean technology.

After the 1980s, the United States and Japan successfully developed the filter object of 0.1 μ m. A new ultra-high efficiency filter with a capture efficiency of 99.99%. Finally completed 0.1 μ M grade 10 and 0.1 μ M 1 clean room, which makes the development of clean technology enter a new era.

With the development of science and technology, China's clean enterprises are also developing rapidly. In Wujiang, Jiangsu Province, there are more than 2000 enterprises engaged in clean equipment, construction and construction.

With the continuous improvement of people's living standards, people have higher and higher requirements for living environment and quality of life. Purification engineering technology has been gradually applied to household air purification. At present, China's purification projects are not only applicable to electronics, electrical appliances, medicine, food, scientific research and other industries, but also likely to go to families, public entertainment and educational institutions. With the continuous development of science and technology, purification engineering enterprises are gradually extended to thousands of households. The scale of domestic purification equipment industry is also growing day by day. People begin to slowly enjoy the effects of purification engineering.

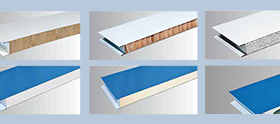

Linsen Linsen purification products are widely used in microelectronics, liquid crystal panels, medicine, biopharmaceutical, hospitals, laboratories, precision instrument manufacturing, automobile manufacturing, spraying, food, dairy products, cosmetics, chemical industry, industry, commerce, construction and other industries.

We hope to provide you with high-quality, energy-saving, low-carbon and high-quality clean environment with professional services, outstanding products and efficient team!